TURNING EMISSIONS INTO OPPORTUNITY

At Next Century-Power, sustainability is built into our power strategy.

Working alongside Inertial, our carbon-capture partner led by Dr. Alec Houpt, we’re advancing a new class of technology designed to remove CO₂ directly from post-combustion exhaust and transform it into high-value carbon materials for commercial use through our sister company, Carbon Edge.

This system closes the loop between power generation and carbon utilization, cutting emissions while creating marketable materials that strengthen the economics of clean energy.

OVERVIEW OF PROJECT SIZES

| SCALE (Metric Tons CO₂ / Yr) | SPACE NEEDED | POWER REQUIRED | CAP EX | COST PER TON | TIMELINE |

|---|---|---|---|---|---|

| 20k / y | 1/2 acre | ~ 2.5 MW | $10M | $30–$80 | ~ 12 mo |

| 100k / y | 1 acre | ~ 9.7 MW | $30M | $30–$70 | 12–16 mo |

| 1M / y | 3–5 acres | ~ 97 MW | $150M | $30–$50 | 16–24 mo |

CARBON CAPTURE PATHWAY

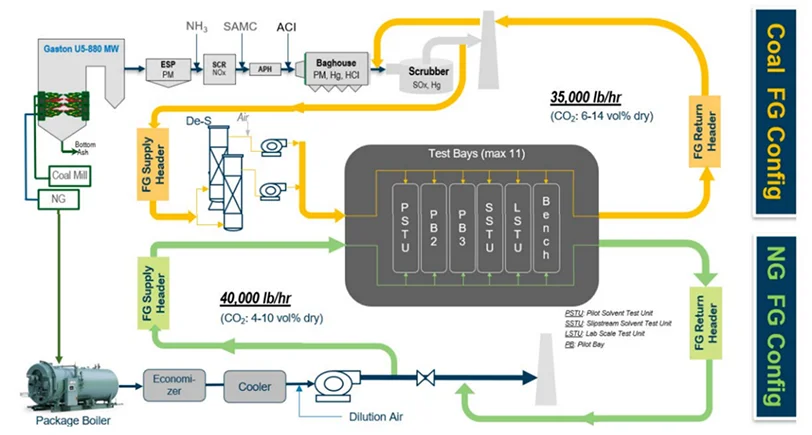

A loop will be made from the power plant exhaust stack, to Inertial’s carbon capture units where the water vapor and CO₂ are removed from the flue gas, then a return header will be used to return all but the water vapor and CO₂ to the exhaust stack. A similar configuration schematic is shown which represents how the National Carbon Capture Center in Wilsonville, Alabama, functions. This style of operation avoids the need for building a new exhaust stack, reduces the flow rate of the exhaust stack and reduces the concentration of water vapor and CO₂ in the flue gas being exhausted.

SEE HOW CAPTURE BECOMES VALUE

Learn how our partnership with Inertial and Carbon Edge is redefining what clean power can achieve.